Didn’t thought about a weak seam either! I find that my 4 mm stitch length doesn’t look good and I wanted to have 1 or 2 mm more.

Didn’t thought about a weak seam either! I find that my 4 mm stitch length doesn’t look good and I wanted to have 1 or 2 mm more.

Thank you very much. You have correctly deduced the sliders, yepp.

Re-engineering would indeed be a fun project and that’s why I was asking for advice.

Stitching by hand didn’t even cross my mind so thank you for thinking out of the box! :)

I understand you know how to change the step length that can be changed now, yes?

Yea

You say <2mm to 5mm. My very similar machine can go to almost 10mm but it cannot keep the thread very tight.

I would die for 10 mm. I would be in to adjust the machine while sewing for any step lenght larger then 5 but 10 mm would be perfect.

This is the limiting thing, the machine, every part, is designed for sewing a length of 2-8mm or whatever. A longer stitch step would need a complete change and probably a stronger motor.

I can change gearings, leverages and axles if I understand what to communicate. I am not bound to the current chassis and motor. I can construct a chassis afterwards rezpecting current alignments within nm.

By moving the knob or lever that changes the stitch step length, you will see what is going on.

I circled the change in blue. Leveraging the handle could be the case but axles wind on their own. It is a mind fuc* which can only be put in perspective by Engineers, imo.

Edit: you edited before me!! But I don’t adress it yet, since you explain the context more professionally. Thank you in this regards.

The machine is more then 40 years old. I attached the photo. The right handle adjust the zick-zack-width (I had to adjust the chassis to get it zero’d) and the left handle puts the needle ‘left’/‘middle’/‘right’ in the feet.

I had to cut some chassis on the right handle to the left and adjust the internal screws so that the axle of stitch width is exactly above the front-needle of the geering. It wasn’t exact with a straight stitch prior to this.

I may add again: Me or my friends are capable of changing any axle or gearing to nm but I do not know what to request in the first hand. Engineering is very, VERY, hard… :(

What thing in my machine is limiting my machine step? The rotation on the inside axle?)

Thank you for your kind words and objective perspective.

Indeed it is. Though I just started to leverage its capabilities.

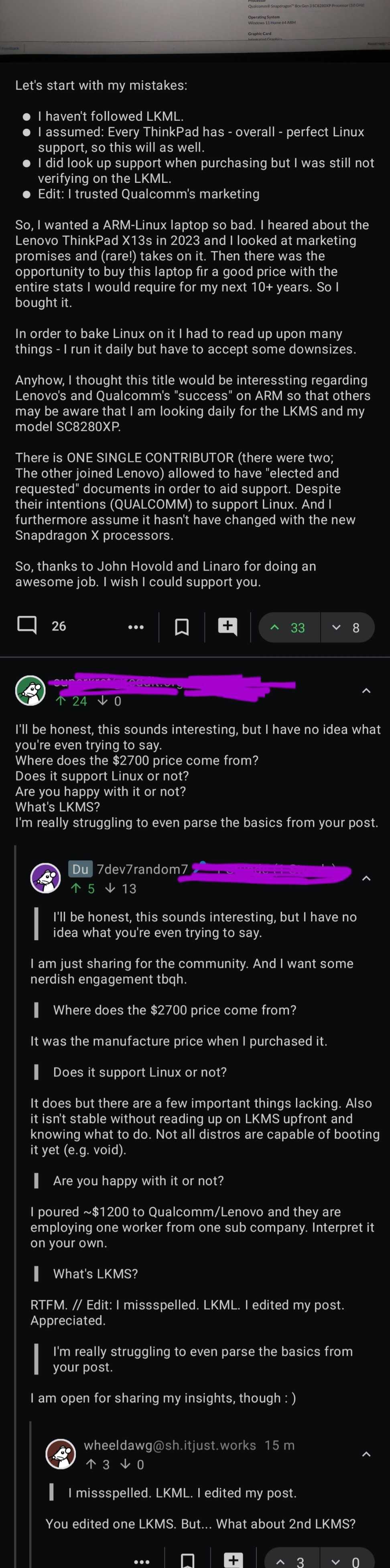

Nonetheless, I would again buy into aarch64.

I will be more sensible the next time and I took my lesson. Thank you for elaborating clearly!

I don’t see myself like this but thanks for your analysis.

I paid 1200 EUR.

You may chime in here: I purchased it with three years of support as well (they [Lenovo] exchanged my brickes speakers, btw).

Thank you for your persistance. Edited it, Sir or Madame.

You are untinted. Tha nk 's for th is, bot.

Of whom?

I edited both:

The listing price was $2700 on purchase. I bought it for around $1800. The $650 dollar are from the Lenovo outlet store. I could sell this laptop for less then $500 on ebay.

More insights I gained using this laptop (intended for the curious Linux enthusiast):

Thisnis slightly out of context. I told to (politely though, I thought) RTFM because the acronym should have been known in this channel. Though I have missspelled it and therefore his question was valuable critique.

I see; Thank you for teaching me. From now on I will try to be more objective and inclusive!

In real life I am known to be upfront (and too fast many times as well). No excuse - just some perspective from myself I have to think about.

I fear this may be the case but since I am not an engineer thought about pulling some opinions here thumbsup