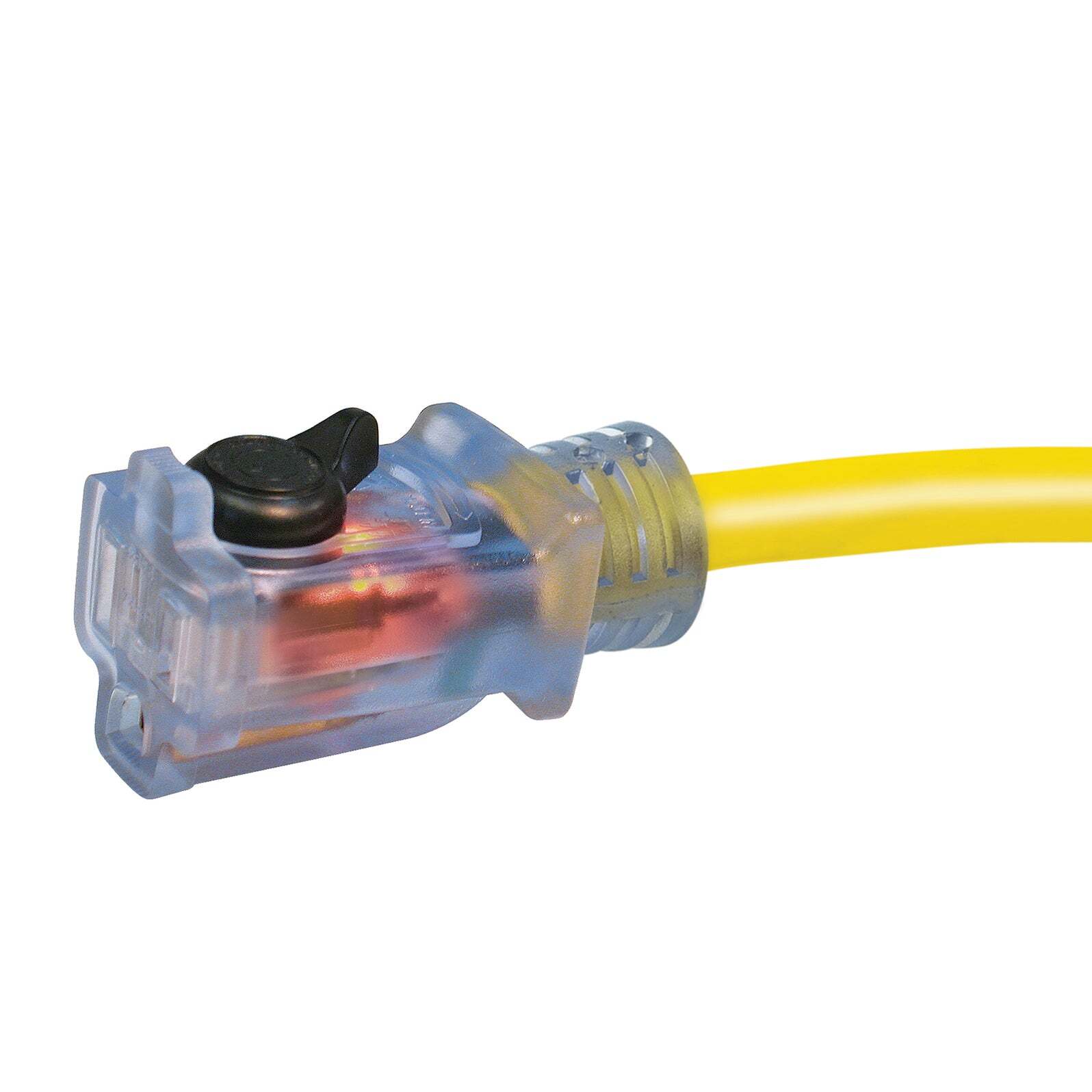

I’m going to disagree with most of these comments. They don’t protect the prong so much as they protect the cord or other objects in the cords vicinity (painted surfaces, fragile surfaces, etc). The little plastic cap that covers tire stems on cars and bikes , while keeping it clean when installed, are primary to prevent chaffing issue on the inner tube whike shipped and stored; same thing with this prong shroud. They have holes in them as to not retain moisture I imagine.

Long story short, the prongs are metal and have corners. They are the strongest, “sharpest” thing in the box. The plastic isn’t protecting the prongs from us, it’s protecting us from the prongs.

I believe it’s to protect the prongs from getting damaged during shipping - and if the container gets rained on or something, it could provide some protection from that

I’m of the opinion that it’s just to improve the perception of package quality. I don’t see those cheap plastic pieces as keeping the prongs from accidentally warping or bending but I guess they could keep moisture away. I’ve never received a corroded set of prongs before their use though so my theory stands as they are upping the packaging visual aesthetics.

Yeah this is probably the most likely. We do love to put plastic on everything.

Could it be to protect the rest of the item from getting scratched by the prongs? Especially a screen, or some soft/glossy plastic case that would be prone to scratches.

Edit: I submitted this right after Hylactor’s top comment and I agree with them!

I think it’s just to stop the prongs from scuffing other things in the same package compartment. Usually you’ll get the cord in a bag or with the plastic but not both. With the cord is in a section of the packaging with other items it keeps them from getting scratched.

The real interesting question is those two holes in the end of two of the prongs.

What are they for?

A long time ago there were two little dimples inside the outlet that corresponded to those holes, they would kind of help snug the cord in place and hold it in. Modern outlets don’t need that anymore since they kind of squeeze the prongs with springs, so why are we still drilling holes in all the plugs?

Well, it turns out, that if you don’t drill them, consumers think there is something wrong with the plug and don’t want to use it. True story.

Apparently, there are places out there and manufacturers that have decided to stop drilling the holes. I’ve seen one or two of those plugs and they immediately look extremely weird.

It’s not really what the holes were made for, but there are some extension cords that have a locking feature; a pair of plastic pins moved by a lever that lock into those holes preventing it from unplugging. Handy for dragging power tools around the shop.

We just always made a loose knot where they joined.

Keeps the cords from coming unplugged and reduces the stress on the plugs

The only time I saw one was on a cheap dollar store plug. I immediately thought it was defective.

This is neat info!

I recently saw a video on this and they said that the holes are used in manufacturing and showed an example. I’ll see if I can find the video.

It was probably the Technology Connections one. Even if not, I strongly recommend his channel.

I like how many of the new top level comments on here are going the way of Reddit already.

One-liners trying to be funny or make puns instead of actually engaging in conversation, indistinguishable from bots. :(

Being funny is engaging in conversation though.

Here’s an actual bot answer:

Those plastic covers for electrical plugs are typically used to protect the plug prongs when they’re not in use. They help prevent the prongs from getting bent, damaged, or exposed to dirt and debris. Plus, they can minimize the risk of accidentally touching the prongs and getting a static shock.

And here’s a joke that I asked ChatGPT to make:

Ah, those little plastic mysteries—probably just trying to keep the plugs warm in the winter!

It’s designed to keep the prongs from collapsing or extending during manufacturing and shipping.

but then the three cover would be connected at the tip? otherwise the plastic is not strong enough to help against deforming?!